Students’ initiative to help build schools

April 07, 2017

April 07, 2017

The alumnus — Frank Sherrill ’07 — a political science graduate living in Guatemala, has been working with others to build “bottle schools,” structures that replace traditional cinder blocks with plastic bottles that community members stuff with non-organic garbage. They are called “eco bricks.”

The foundations, columns and beams for the buildings are made of reinforced concrete; eco bricks are attached to a metal frame and anchored with chicken wire to fill the space between structural elements. The purpose is twofold: the schools are cheaper to construct than their traditional counterparts, and Guatemala’s notorious garbage problem is addressed in the process. But one issue Sherrill has encountered is the amount of time it takes workers to fill the bottles.

Monferrato and fellow seniors Madison Gegeckas and Rachel Davis thought they could help.

“The current fill process involves stuffing the trash in the bottles manually. It takes one person 30 minutes to fill a bottle,” said Monferrato. “We set out to build a machine that could stuff multiple bottles at a time. It needed to be time-efficient, durable and affordable.”

The students were introduced to Sherrill through David Ives, executive director of the Albert Schweitzer Institute at Quinnipiac. Sherrill, a former Peace Corps volunteer, is president and co-founder of HAZSE, a social enterprise company that works with communities to construct bottle schools.

After investigating the problem and interviewing Sherrill, the trio began brainstorming. First, they investigated using a foot- or arm-operated push-stick to stuff trash into five bottles at a time.

“We scrapped this idea within a week,” said Monferrato. “One reason was because it was a little too easy; we wanted to challenge ourselves more. The technical concern was that the push-stick only hits the center of each bottle, so it’s not hitting the trash on the outer sides of the bottle.”

Their next idea involved using a centrifuge. This idea was abandoned for several reasons, including high expenses. Their third—and final approach—involved building a contraption that incorporates a three-step process: loading, packing and compressing. During the third step, bottles will automatically tilt to facilitate compression of the garbage. The pedal-operated machine should be able to stuff five bottles in five minutes.

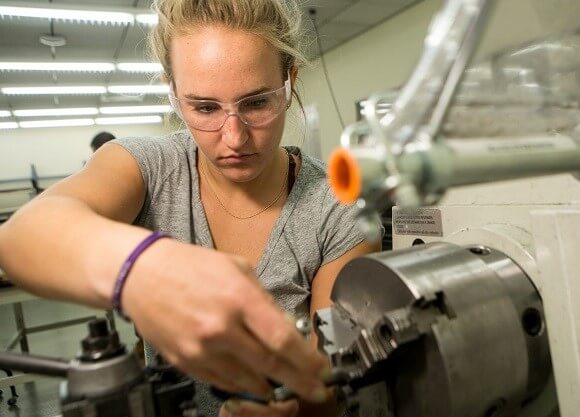

Next, the students headed to the machine shop in the lower level of the Center for Communications and Engineering to build the packing machine. The final step involves testing, which will begin in April.

“Unlike in Hollywood, the prototype almost never works,” said John Reap, assistant professor of mechanical engineering.

“While we’ve anticipated some issues, there will undoubtedly be more. You have to rethink what you’ve been doing and then modify the machine. This is called iteration, and it is very much a part of design.”

Adds Monferrato: “Something might get loose or a lot of wear could occur. We also want to make sure that the machine is sustainable.”

Once the device is built, the team plans to give it to Sherrill so it can be used in Guatemala. The students are excited at the prospect of helping local villages thrive. In fact, they have purposely ensured that their machine will not be fully automated because they don’t want to cut out all manual labor.

“In order for this to work, the entire community has to get involved,” said Monferrato, noting that adults and children regularly come together to stuff bottles. “It’s very empowering for them.”

Quinnipiac Today is your source for what's happening throughout #BobcatNation. Sign up for our weekly email newsletter to be among the first to know about news, events and members of our Bobcat family who are making a positive difference in our world.

Sign Up Now