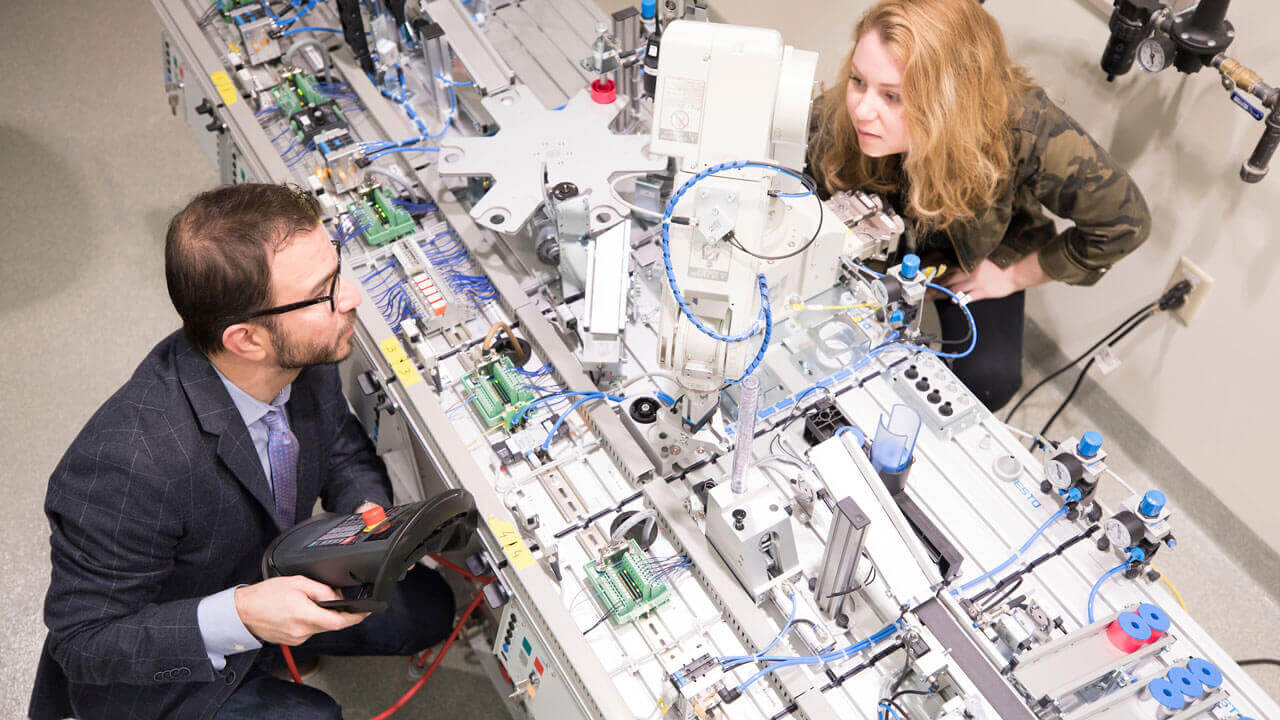

As you work towards your BS in Industrial Engineering, you will learn how to design and implement systems and processes that effectively coordinate people, machines, materials, energy and other resources to eliminate waste, increase output and ensure quality. A range of state-of-the-art facilities such as our performance optimization lab will give you a hands-on education in the many human and technological factors at play each day in any number of complex systems.

Throughout the program, interdisciplinary research projects will acclimate you to working in teams with other aspiring engineering professionals, while internships in professional settings such as Port Authority of New York & New Jersey, Hartford Hospital, Pratt & Whitney and Medtronic prepare you for a successful career in industrial engineering.

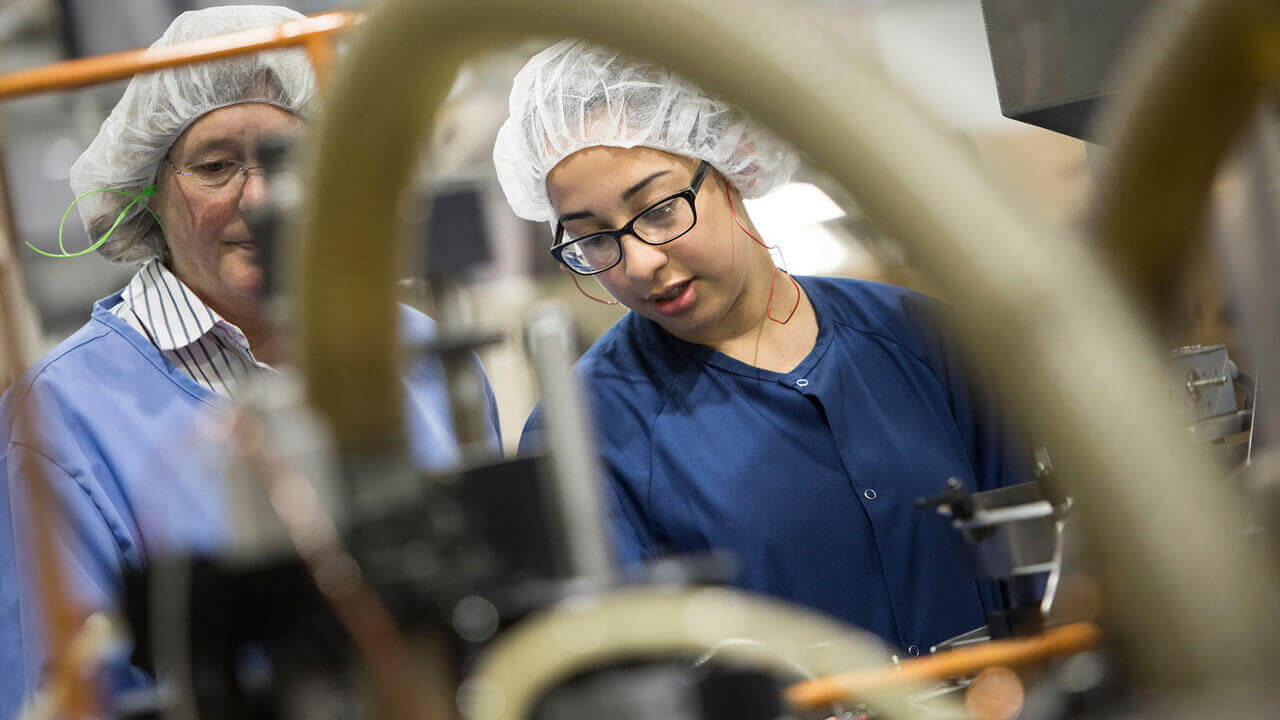

Our curriculum is hands-on, career-focused and flexible, with a particularly strong emphasis on the fields of manufacturing, healthcare and supply chain. Students are encouraged to tailor their studies within one of our three optional concentrations that align with their career goals.

Optional Concentrations:

-

Automation Systems and Robotics

-

Healthcare Systems Engineering

-

Ergonomics and Human Factors

For students interested in continuing on to advanced study immediately following the completion of their undergraduate degree, our accelerated dual-degree program enables you to earn either a BS and MBA in 5 years or a BS and JD in 6 years.

Learn more about the 4+1 MBA program

Learn more about the Accelerated 3+1 MBA program

Learn more about the 3+3 JD program